EQUIPMENT, SYSTEMS & PROGRAMS

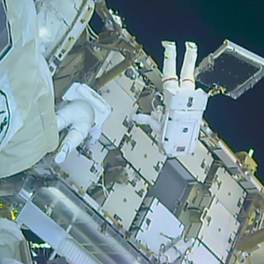

A s our companies have grown, so have our space program offerings. Today, Atec offers complete program execution for complex equipment and systems. Earlier emphasis was on Atec’s proven abilities to manufacture critical launch and flight components. Full design using Model Based Definition, CNC/CMM techniques and high pressure testing has since followed. Today, with our success involving rocket engines, electronic modules, space capsule components, ISS and environmental testing, Atec is now offering full Program Management services for critical component streams, complex equipment lines and major systems.

A s our companies have grown, so have our space program offerings. Today, Atec offers complete program execution for complex equipment and systems. Earlier emphasis was on Atec’s proven abilities to manufacture critical launch and flight components. Full design using Model Based Definition, CNC/CMM techniques and high pressure testing has since followed. Today, with our success involving rocket engines, electronic modules, space capsule components, ISS and environmental testing, Atec is now offering full Program Management services for critical component streams, complex equipment lines and major systems.

Following NASA’s announcement of Atec as their Subcontractor of the Year in April 2017, we have seen the volume and breadth of our space business inquiries grow dramatically. Atec is performing on programs for the major U.S. rocket launch teams. Additional engineering and program personnel have been added, now with over 130 engineers in our 67 year old organization. Atec’s renowned remanufacturing and technology refreshment capabilities have led to unique projects to modernize and extend service of critical aerodefense assets.

Test facilities for high pressure gaseous and hydrostatic testing up to 20,000 psi with blast rating approaching 2 million foot pounds have recently been constructed. New CNC multi-axis machining and 3D Printing centers have been added to increase our capabilities and speed. Atec demonstrated our longstanding quality management system commitment by recently renewing our AS9100 certification to Revision D. Atec is proud to play a larger program role for our space industry customers.