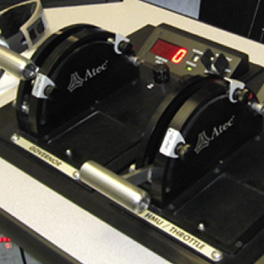

ENGINE THROTTLES

A tec’s Model 5400 Series Electronic Engine Throttle System replaces antiquated mechanical and electrical throttles used in the testing of a variety of engine types. It enables fast changeover between engine types in the same hush house or test facility. Designed, used, and improved for over 10 years in both commercial and military engine test markets, the Electronic Engine Throttle System is compatible with both FADEC and mechanical PLA engines. It is available in a single throttle control version to support thrust engine variants, and a multiple control version to support the turboshaft/turboprop engine market.

A tec’s Model 5400 Series Electronic Engine Throttle System replaces antiquated mechanical and electrical throttles used in the testing of a variety of engine types. It enables fast changeover between engine types in the same hush house or test facility. Designed, used, and improved for over 10 years in both commercial and military engine test markets, the Electronic Engine Throttle System is compatible with both FADEC and mechanical PLA engines. It is available in a single throttle control version to support thrust engine variants, and a multiple control version to support the turboshaft/turboprop engine market.

As an additional benefit to military customers, the model 5400 is a direct approved fit into the USAF’s A/M37T-20 cab used in Mobile Engine Test Systems, as well as all T4 test cell noise suppressors. The Atec Companies also offer legacy and upgrade throttles and control systems for many US Navy and Allies engines.

Operator Interface Unit

- Counter top space: 7.25” x 13.25”

- Lower box: 11” x 5.75” x 5.19”

- Power: 90 – 250 VAC, 50/60 Hz

- Standard unit does not require other rack-mounted panels

- Drop-in replacement for most applications

- Increment/Decrement switch provides separate control if necessary

- Universal joint interface & splined collar between engine interface & PLA

Engine Interface Unit

- Dimensions: 5.38” x 13.5” x 4.88”

- Motor torque rated below 100 lbs.

- Provides precision movement with continuous & smooth actuation

- Energized motor protected from vibration-induced rotation

- Adaptable cabling

New Automated Version Available

Key Features

- Compatible with commercial & military applications

- FADEC and mechanical PLA equipment options

- Multi-control operations available for turboshaft/turboprop engine applications (Option for dynamometer controls)

- Enables fast engine changeover

- RS232 output for data acquisition/control system

- Precision control

- Smooth operation

- Replaces Space Corp., Shaw & Estes, PCT, Control X, X Tech and Boat type legacy throttles

- Interfaces with all other modern digital DAS controls

Engines

- F100

- F101/F110

- F124/125

- TF34

- J85

- TFE 731

- TPE 331

- TF30

- F404/414

- F118/F119

- T38

- T53

- T55

- T56

- AE2100

- T63

- T64

- A250

- RR300

- PT6

- T700/701

- J52

- J58

- JT8

- JT9D

- JT15

- J79

- CFE731

- CF34

- CF700

- CF6

- CFM56

- V2500

- 501C/D

- Others